Železiarne Podbrezová

Research and Innovation for a Sustainable Future

At Železiarne Podbrezová, we believe that the green transformation must be built on knowledge, technological progress, and the courage to innovate. Through our subsidiary ŽP Research and Development Centre Ltd., we explore new pathways towards more environmentally friendly, efficient, and safer steel production. We work on research and development projects with both European and regional impact, delivering tangible results in emission reduction, operational digitalisation, and improvements in quality and energy efficiency.

Our focus areas include:

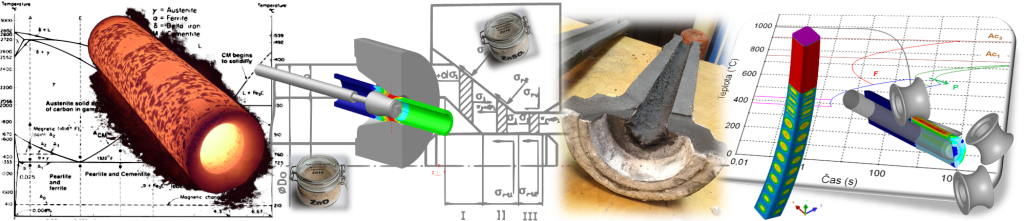

- development of new low-emission technologies in steel production processes,

- improving product quality while reducing environmental impact,

- implementation of digital solutions for automation and operational monitoring,

- development and testing of new refractory materials and processes.

We cooperate with universities, research institutions, and technological centres, actively contributing to the solutions for challenges brought by the green industrial transition and European legislation in the areas of ESG and the EU Taxonomy.

Our research approach covers the entire process cycle:

Identification of production issues

The starting point of every research project originates in real production operations. Production staff, technologists, and specialists identify challenges or opportunities for improvement-whether related to energy savings, emission reduction, improved product quality, or increased process efficiency.

Design of a research solution

Research teams at ŽP Research and Development Centre (ŽP R&D Centre) design specific experiments, models, or technological concepts that may lead to solving the identified challenges. In doing so, we cooperate with universities, expert institutions, and development partners.

The proposed solutions are tested in a controlled environment. We verify new material compositions, physico-chemical properties, material flows, or software models, while continuously assessing their practical applicability.

Pilot operation in production

Following successful laboratory testing, the solution moves into pilot testing directly within the production process—on a small scale or in individual production units. We monitor performance, safety, and environmental indicators.

Implementation and monitoring

The solutions are then implemented into real operational conditions. We monitor their benefits, such as energy savings, emission reductions, cost reductions, improvements in product quality, and optimisation of production cycles.

The changes are documented, evaluated, and disclosed as part of our ESG and EU Taxonomy reporting. The result is concrete data—showing how much CO₂ we have reduced, how much energy we have saved, and how the technical parameters of our production have improved.